Technical Services Manager,

Corteva Agriscience

Maturity and Moisture

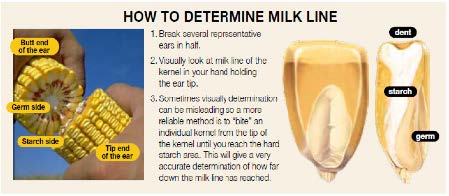

Recommendations vary with different storage structures (e.g. drier in vertical stave/sealed silos to prevent excess effluent). Proper maturity assures adequate fermentable sugars for silage bacteria and maximum nutritional value for livestock. Maturity has a tremendous impact on moisture to help exclude oxygen and thus reduce porosity of the silage. For “dairy quality”silage, the “ideal” harvest maturity/moisture for healthy corn silage plants is 3/4 milk line (>62% moisture).

Length of Cut

It is difficult to offer generalized chop length recommendations because proper length depends on several factors including: 1) the need for physically effective fiber (peNDF) levels in the ration, 2) particle size of the other dietary ingredients, 3) the type of storage structure, and 4) silage compaction capabilities and unloading methods (e.g. silo unloaders, bunker facers). Other factors affecting chop length include the need to chop finer to damage corn kernels if on chopper processing is not available or if chopping longer to compensate for particle reduction from bagging or feed mixing. In general, shorter chop tends to improve compaction in the storage structure and also increases surface area of fiber (or kernels) to improve rate of digestion by rumen bacteria or intestinal enzymes. Longer chop increases the peNDF of the feed; however, excessive length can contribute to sorting by cattle in the feed bunk. It is best to work with the harvesting crew and nutritionist to decide on the proper compromise; recognizing that particle length in the final ration is what is most important. Start at the feed bunk and work backwards as to the amount of each feedstuff in the ration and how much peNDF each one of those feeds need to contribute to the entire diet.

Figure 1

CORN SILAGE

How to Forecast and Determine Milk Line

| Progression of milk line during R5 (dent) stage | Average per Substage | |||

| R Stage | % Kernel Moisture | Kernel Dry Matter Accumulation (% of Total Dry Weight) |

GDU | Days |

| 5.0 | 60% | 45% | 75 | 3 |

| 5.25 (1/4 milk line) | 52% | 65% | 120 | 6 |

| 5.5 (1/2 milk line) | 40% | 90% | 165 | 10 |

| 5.75 (3/4 milk line) | 37% | 97% | 205 | 14 |

| 6.0 (Physiological Maturity) | 35% | 100% | 360 | 360 |

| Total (Average) | 575 | 33 | ||

The continued health of the overall plant allows for continuation of photosynthesis and the deposition of sugar through the vascular system of the plant. In essence it is the “laying down of starch” in healthy plant that reduces the water content of the kernel. Thus, healthy plants are quicker at lowering their kernel moisture than those that are impaired (drought, disease, etc.). The transformation of sugar to starch is dependent on the pathway remaining not only open but steadily fed, in effect, a two way valve, at the kernel attachment to the cob. It is clear what can happen when the inputs lag (aborted kernels near the tip) or where supply (and extremity, farthest away from the source), slow the process (which can even induce premature black layer). Most people assume the kernel “air” dries from the pericarp, but prior to black layer the general consensus is that there is very little moisture movement across the pericarp. After black layer (the two-way valve now closed), kernel drydown is through the pericarp and dependent upon environmental weather and genetics. Within hybrids there appears to be varying genetic difference in levels of porosity affecting their ability to dry down quicker than comparable\ maturity hybrids. During corn maturation, the dry matter of the entire plant, being composed of stover and grain, increases for two reasons:

1. First, the stover is drying as leaves dry and stalks brown. Given that NDF digestibility decreases as plant tissue dies, NDFD also should be dependent primarily on dry matter (DM) content of the stover, not on DM content of the full plant (including the ear) because it should vary primarily.

2. Secondly, grain, being the driest portion of the plant, is still being deposited when plants are healthy. The ear is always drier than the stover, so an increase in the ear to stover ratio increases not only the total plant dry weight but also the percentage of DM in the total plant. This could indicate that waiting until the plant is over 30% DM might not prevent seepage if the plant is still fully green and growing but the kernel has reached the black layer stage as sometimes happens in geographies producing very tall, healthy plants. Overall, this supports the idea that both kernel milk line and whole plant DM should drive the time to start harvesting silage. And secondly, high chop decisions to potentially improve NDFD should be based on stover DM and the amount of dead tissue (perhaps of the lowest foot of the plant in particular) and not on DM content of the entire plant. Research studies clearly show that fiber digestibility declines only minimally in healthy corn plants as they dry down from 30% dry matter to 38% dry matter (70% to 62% moisture). The combination of healthier plants in the fall, the need for starch to increase yield and digestibility and the ability to achieve higher compaction densities in bunkers/piles has allowed growers to harvest corn silage at ¾ milk line rather than 1/3 to 1/2 milk line which was common in the past. Producers who lack the ability to process (roll) kernels on the chopper may have to harvest at earlier kernel maturities and/or shorten the chop length to ensure adequate kernel processing at the cutter head.

Kernel Processing

Kernel processing of corn silage has long been popular in Europe and started to gain acceptance in North America in the late-90’s with the introduction of choppers that came from the factory with the kernel processor (on-board roller mill) as standard equipment. Pioneer has developed a simple field test for degree of kernel damage using a 32-ounce cup. Producers are encouraged to sample several loads each hour by filling the cup level with silage; spreading the sample out and quickly picking out every whole and half kernel. If that number exceeds 2-3 kernels, it is important to discuss with the chopper operator how to improve kernel processing. If left unattended, the result will be a loss in energy as unprocessed kernels escape ruminal and intestinal digestion. Validation of degree of kernel damage can be further accomplished by collecting fecal samples from 10-12 cows and submitting to a lab for fecal starch analysis. The goal is to have less than 3-5% starch in feces. Levels higher than that could indicate poor processing of corn silage (or other starch sources) resulting in inefficient use of dietary starch in addition to possibly predisposing cows to maladies such as hemorrhagic jejunum (or bowel) syndrome (HJS or HBS).

There are several factors that chopper operators can check to improve processing: length of chop (longer typically more difficult to damage kernels), roller mill wear (life of 400-1000 hours depending upon mill), roller mill gap (1-3mm depending upon chop length and kernel maturity), aggressiveness of the rolls, and perhaps the most important, roller mill differential (typically 20-40%). There have also been recent innovations in roller mill design and differential speed including Shredlage® (Claas) and KernelStar Technology (John Deere).

This article was written for the Winter 2022 Dairy Eastern Dairy Grist. To read the whole Dairy Grist, click the button below.