By Dr. Martin Clunies, Bruce Schumann, M.Sc. & Adam Totafurno, M.Sc.

Monogastric Nutrition,

Grand Valley Fortifiers

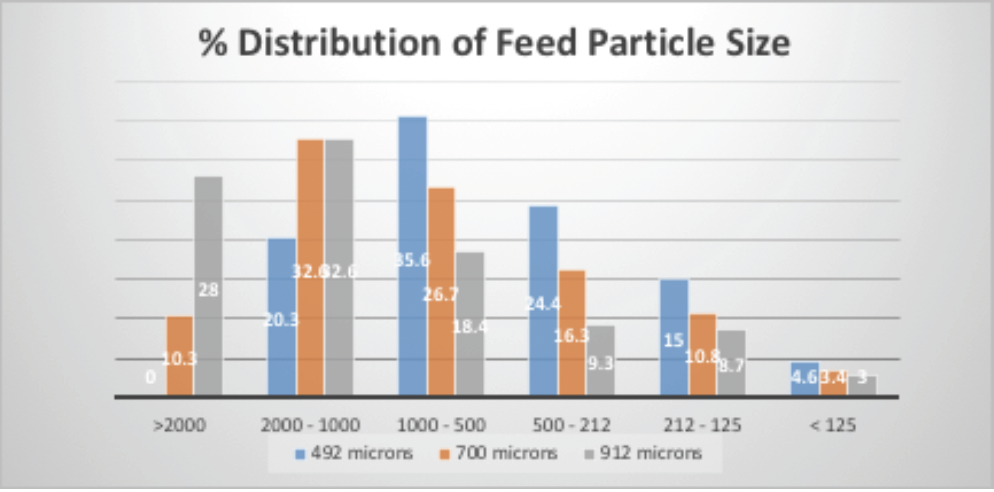

While the bird may have preference for certain particle sizes, getting the feed to be representative of that preference is quite challenging. There are two ways to grind feed ingredients to the desired particle size; by using a hammer mill in combination with screens or using a roller mill. The hammer mill is the most common piece of equipment used, due to its low investment/purchase cost, its capacity to grind a large amount of feed and the ease of setup. Roller mills, on the other hand, are more expensive to purchase, less expensive to operate, a bit more difficult to set up, but they provide a feed of more uniform particle size. Getting the correct particle size is part science and part art. For example, if we look at corn ground to a target average of 492, 700 and 912 microns particle size one can anticipate particle distribution as shown in Figure 1. This distribution is affected by quality of the grain, screen size opening and the speed at which the grain is ground. Mash feeds are made up of a combination of ingredients of different particle sizes, presented to birds they selectively consume those particles which are preferential based on age and beak dimensions.

Figure 1. Particle size distibution of 492, 700 and 912 micron corn grain Particle Size.

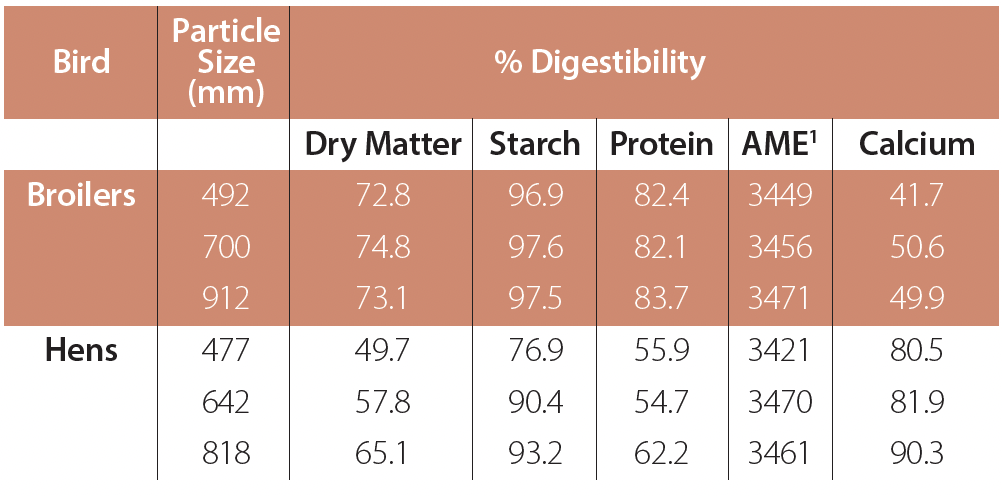

Based on the fact that broilers appear to like feed with a range of particles from 1.5 to 3 mm (Ross 708 Management Guide 2018), one would anticipate that young broilers would consume those feeds with greater particle size. While particle size is most important in increasing the surface area for enzymes to digest and absorb nutrients absorbed, feed particle size also affects gut health. Smaller particle size results in a more rapid flow of feed through the digestive tract. This finer fraction of feed will end up being fermented by pathogenic bacteria because the endogenous enzymes wont have sufficient time to degrade the feedstuff and absorb the resulting nutrients. What is most important is the proportion of feed which is less than 215 microns particle size. Recent experimental results with broilers and laying hens suggest that increasing particle size improves overall digestion of energy, starch and protein (Table 1).

Table 1. Effect of feed particle size on percent digestibility of dry matter, starch, protein AME and calcium of broilers and hens.

Any parameter which increases enzyme efficacy has a major impact on nutrient utilization and growth of young birds, less than 14 days of age. As the bird grows and feed intake accelerates, the impact of reduced particle size on hindgut fermentation decreases the number of beneficial lactobacilli present, while the number of pathogenic bacteria such as Clostridia, E. coli and Campylobacter species in the lower gut is increased.

What was most surprising was the impact grain particle size had on the digestibility on calcium in laying hens, when the particle size of the calcium source was constant across all treatments. How could the particle size of the grain affect digestibility of this uniform calcium source? There are two possible explanations; 1) feed with larger particle size was retained in the upper tract and gizzard of the bird and hence more calcium was solubilized, ground or both prior to entry into the lower digestive tract where the calcium is absorbed or 2) the improved gut health resulted in better digestion and absorption like the other nutrients of the diet.

Table 2. Effect of feed particle size on body weights of 21, 32 and 40 day old broilers.

This article was written for the Spring 2021 Poultry Grist. To read the whole Poultry Grist, click the button below.